How Cooling Towers Can Save You Money

Here’s a biggie: The storage of cooling water has become a very cheap part of the overall energy production. And that saves you money.

Until recently, cooling water storage was pretty expensive, in the $60,000 – $150,000 per tonne range. Then in the early 2000s cooling technology companies produced what was initially a way to cool lawns. However, they were subsequently instructed to focus on cooling the likes of aircraft and ships. After years of experimenting with new coolers, the technology contained in the coolers dominating the market started to be deployed on power plants.

More recently, companies have started using the developed systems to cool boilers, and certain companies have now invented a storage solution for air conditioning that is similar to cooling towers. It may be some time before you see the coolers in your garage, but when you see them, you’ll be happy you don’t have to pay a cent for the cooling that would otherwise have cost you $150 per tonne.

How Does It Work?

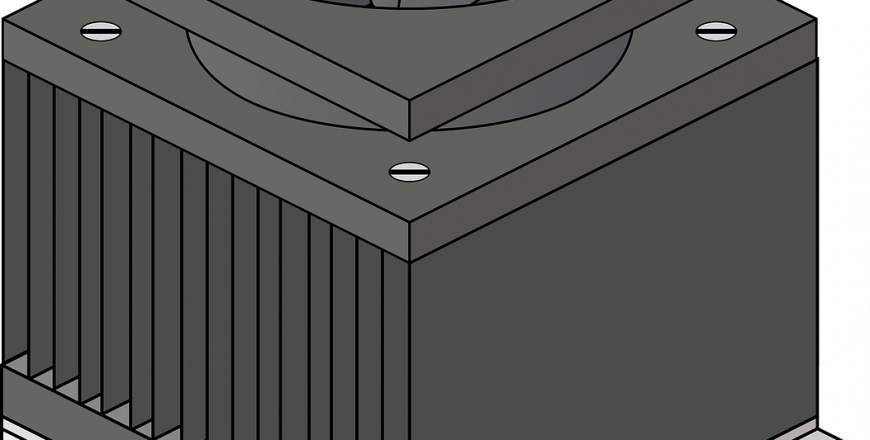

You can cool things in two ways: mechanically or electrically. Mechanical cooling systems work by using gravity and the natural cooling effect. They draw in warm air, which rises, cools down, and then passes over cold pipes to cool even more. The now cooler air falls back down, repeating the cooling process. Some systems use mesh wire screens or louvers to control airflow and evenly distribute water, keeping out debris and improving cooling. These screens also work as filters, catching particles and making cooling more efficient. This combination of mechanical cooling and mesh wire screens can ensure your cooling system works well, providing consistently cooled air and maintaining air quality. If you’re looking for mesh wire screens for your cooling system, you can try here.

Meanwhile, electrical cooling works the same way: electrical conductivity is a big part of the cooling process. You need to cool the air so you can move it around. And there’s another huge advantage – an electric cooling system requires only the minimum electrical power. It can be made much smaller, and the amount of electricity used per tonne of cooling water is a lot lower. This makes electric cooling extremely energy efficient. Companies might also explore other ways of energy production, such as Uranium Mining, to generate and provide electricity for the large-scale cooling processes at their plants.

In the pursuit of energy-efficient cooling systems, temperature monitoring plays a crucial role, and highly valuable sensors like thermocouples can come into play. By integrating thermocouples into cooling towers and mechanical storage systems, operators can precisely control and optimize the cooling process. The data collected by thermocouples enables real-time adjustments, ensuring the cooling system operates at its peak efficiency. As companies explore innovative ways of energy production and implement advanced cooling technologies, leveraging appropriate thermocouple types for precise temperature monitoring will undoubtedly contribute to even greater energy savings and overall system performance.

Two Cooling Towers Equivalent to Two Inverters

By cooling the water to a liquid, it can be stored and heated in the future for refrigeration. The cooling process is called convection, and it occurs at a relatively slow rate: 2.5 kilohertz, which is 4% of the rate at which the heat flows through the cooling tower. Therefore, it will need less energy to heat the water back up to its normal temperature. A typical 1 MW power plant can take one cooling tower for heating water that uses a cooling process with a power of 4 MW.

Cooling towers can store roughly 20% of the energy used to cool the air and produce it back into electrical power.

Thanks to advancements in custom cooling systems technology, it’s now possible to cool things down using only mechanical storage. Even at an energy-efficient rate of 2.5 kilohertz, it will still be cheaper to cool your garage using mechanical storage than to use electrical cooling.

To get all this energy efficiency, you need a strong mixture of policies to encourage the reduction of energy waste. For cooling water systems, you need incentives to invest in better cooling technologies.